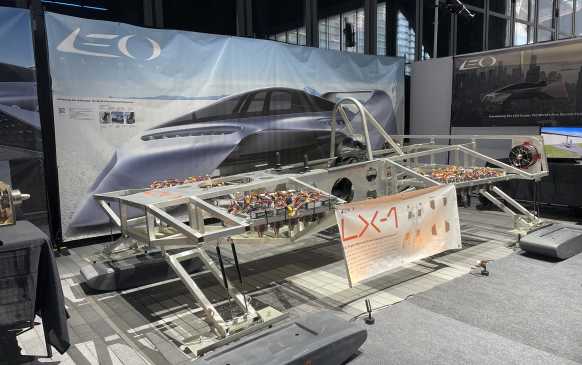

LEO Flight’s LX-1 skeletal prototype on display at the Greentech Festival in New York City last year.

Electric flying car startup LEO Flight is preparing to raise funds to begin work on its first preproduction prototype of its LEO Coupe vehicle, marking progress toward the development of one of the most unique electric vertical takeoff and landing (eVTOL) designs in the personal use category.

LEO Flight is developing a flying electric supercar capable of carrying a pilot and three passengers or 510 lb. up to 250 mi., including reserves, with a target cruise speed of 200 mph. The aircraft is designed to resemble a supercar, with a sleek carbon-fiber exterior and wraparound double box wings. It will be powered by a novel system of 200 clustered electric lift jets stored underneath the fuselage, with six horizontal thrusters in the back of the aircraft for forward flight.

The LEO Coupe is being designed to handle like a normal car, fit into an urban garage and charge up using a normal electric vehicle (EV) charging cable. No infrastructure is required to install for takeoff and landing, although the company is also designing vertistops that could be installed in parking centers or on rooftops to enable a network of pads from which aircraft could take off, land and charge up.

“The LEO Coupe is very automotive in nature, and it’s designed to be used the same way you’d think of using your car–the practicality of leaving your house and jumping in the car and taking off to wherever you’re going,” says LEO Flight co-founder Carlos Salaff, who previously worked as a senior designer at Mazda. “It’s taking that simplicity and convenience, and blending it together with the speed and freedom that an airplane gives you.”

The company has raised around $580,00 in a pre-seed funding round, with proceeds used to finance the assembly of its LX-1 prototype, which consists of a skeletal airframe decked out with the electric cluster jet propulsion system. That vehicle has been used for manned and unmanned tethered hover testing. The company is currently getting ready for an initial fundraising seed round that it will use to finance assembly of its LX-2 preproduction vehicle, which would include the full carbon-fiber skin along with the propulsion system that is currently being proved out on LX-1.

While R&D is being done in both Indiana and New York, physical prototyping and testing of vehicles is primarily taking place in Indiana, where LEO Flight plans to migrate its manufacturing and R&D headquarters later this month.

The LEO Coupe’s electric lift jets are small modules that weigh around a pound each, with relatively low voltage of around 25 volts and each producing around 11.6 lb. of thrust, according to LEO Flight Co-Founder Pete Bitar. The jets can be easily arranged in various configurations like Lego blocks, and thanks to their small size can work with smaller-sized batteries than other eVTOL designs.

Bitar also said the electric jet design offers numerous advantages over propeller-driven eVTOL aircraft, especially when it comes to fast intercity travel, as electric jets are more efficient than propellers in terms of distance per charge. And with 200 clustered lift jets, the vehicle has massive redundancy and can lose as many as 60 jets without serious issue.

“I can go three times faster with these jets for the same amount of kilowatts compared to a propeller,” Bitar says. “Having open props is also dangerous for people and for infrastructure. What happens if you’re in liftoff mode and there’s a failure? The amount of margin around safety in that scenario is unbelievably dangerous.”

LEO Flight hopes to certify the vehicle under the FAA’s Mosaic framework for light sport aircraft and anticipates initial deliveries as soon as 2025.