To capture the emerging demand for aircraft storage, transition and dismantling in China, Airbus is joining forces with specialist Tarmac Aerosave and the city of Chengdu.

Airbus is anticipating that the Chinese market will mature as Western markets did. In other words, fleet aging will create needs and accompanying business opportunities throughout an aircraft’s entire life cycle. Airbus wants to address these in the framework of China’s “Green Industry” strategy. The five-year plan, unveiled in December, notably aims at boosting the use of recycled material.

- Airframer already sees unmet storage need

- Recycling specialist Tarmac Aerosave seizes opportunity to expand

Airbus, Tarmac and the city of Chengdu emphasize that the project they are jointly developing supports the principle of a circular economy that addresses the whole life cycle.

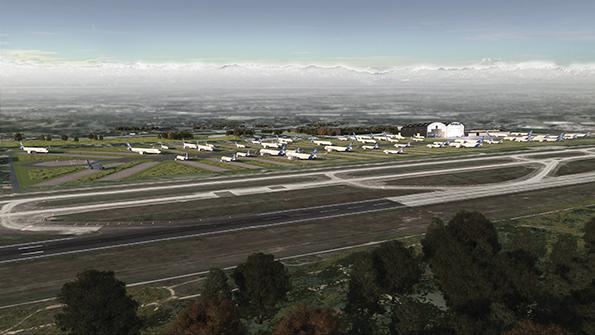

The three partners are working out the details of creating a “sustainable aircraft life-cycle service center” that will feature a storage capacity of 125 aircraft on 80 hectares (200 acres) at Chengdu Shuangliu International Airport by 2023. The site is predicted to employ 300 people by 2030.

Between leasing contracts, a commercial aircraft may have to be stored. It may also have to undergo maintenance and upgrade work in that transition phase, such as receiving a new cabin layout and livery. “Chinese lessors store two-thirds of their aircraft outside the country, whereas they tell us they are looking for a solution in China,” says Wolfgang Kortas, head of Airbus’ life-cycle solutions development.

Future Chinese needs have also been identified in aircraft end-of-life services. Those include aircraft dismantling and used serviceable material (USM) distribution. A two-digit growth rate is expected over the next few years, Kortas says.

All those skills are the kind that Tarmac Aerosave—jointly owned by Airbus, Safran Aircraft Engines and Suez—has grown in France and Spain. Tarmac’s know-how includes aircraft storage, maintenance, transition and recycling. The company has focused on environmentally friendly processes, such as a giant chainsaw-like system that recovers all cooling water and dust when the airframe is cut apart.

Burgeoning demand in China and existing capabilities at Tarmac led Airbus to look for a way to establish a comprehensive facility. Chinese needs in recycling are not being met, Kortas says. “There is no such thing as the one-stop shop we will build,” he adds.

The project was launched three years ago. “We met players on the Chinese market such as carriers, lessors, [maintenance, repair and overhaul] service providers, appraisers and the Civil Aviation Administration of China (CAAC),” he says. “We drew a picture of the market’s dynamics.”

Chengdu was chosen for its mature aerospace industry. “They are used to that sort of project,” Kortas says.

In Tarmac’s perspective, Airbus is bringing its strength in China to the partnership. “Airbus already has high visibility in China and a local market,” says Tarmac President and CEO Alexandre Brun. “Leaning on Airbus gives us more possibilities.” The airframer has 25 legal entities in the country, including joint ventures with Chinese partners.

A formal accord is expected to be signed in the middle of the year. It is planned to lead to a start of operations late in 2023, subject to regulatory approvals.

The form the Airbus-led cooperation effort will take has yet to be determined. “We are finalizing the details of our agreement,” Brun says. “The city of Chengdu will have a key role in infrastructure and local support.” Tarmac plans to hire local employees and train them, either in China or Europe.

Co-located with the future company, Airbus subsidiary Satair will take care of purchasing aging aircraft. A specialist in spare parts, the company will order aircraft dismantling services from the newly created organization. Satair will market used components, thus acting as a broker.

“In 2020, the CAAC issued a rule on reusing USM outside the fleet they come from,” Kortas says. “This gives us a solid regulatory basis to grow the USM market.”

Activity at Tarmac’s sites in Tarbes, France, Teruel, Spain, and at Toulouse-Francazal Airport, is still very much influenced by the COVID-19 crisis. At 180 in 2021, the number of aircraft coming in for maintenance declined after a strong 2020. “Our storage areas are full, and we had to turn down some requests for aircraft storage,” Brun says. “We have seen the number of parked aircraft grow by 56% in two years.”

In terms of aircraft returning to service, Tarmac saw a modest increase: up to 130, over the previous year’s 115. “In 2019, returns to service stood at 144, and we are still largely below that level,” Brun says.

In contrast to the healthy storage business, a drop in demand can be felt in aircraft recycling. “Owners lack visibility on used-parts demand,” Brun says. “They are waiting for a recovery to solidify, especially in widebodies. Therefore, they choose to wait and store an aircraft before embarking on a dismantling process.”