Opinion: How Can A&D Reduce Risk? Fully Adopt Digital Transformation

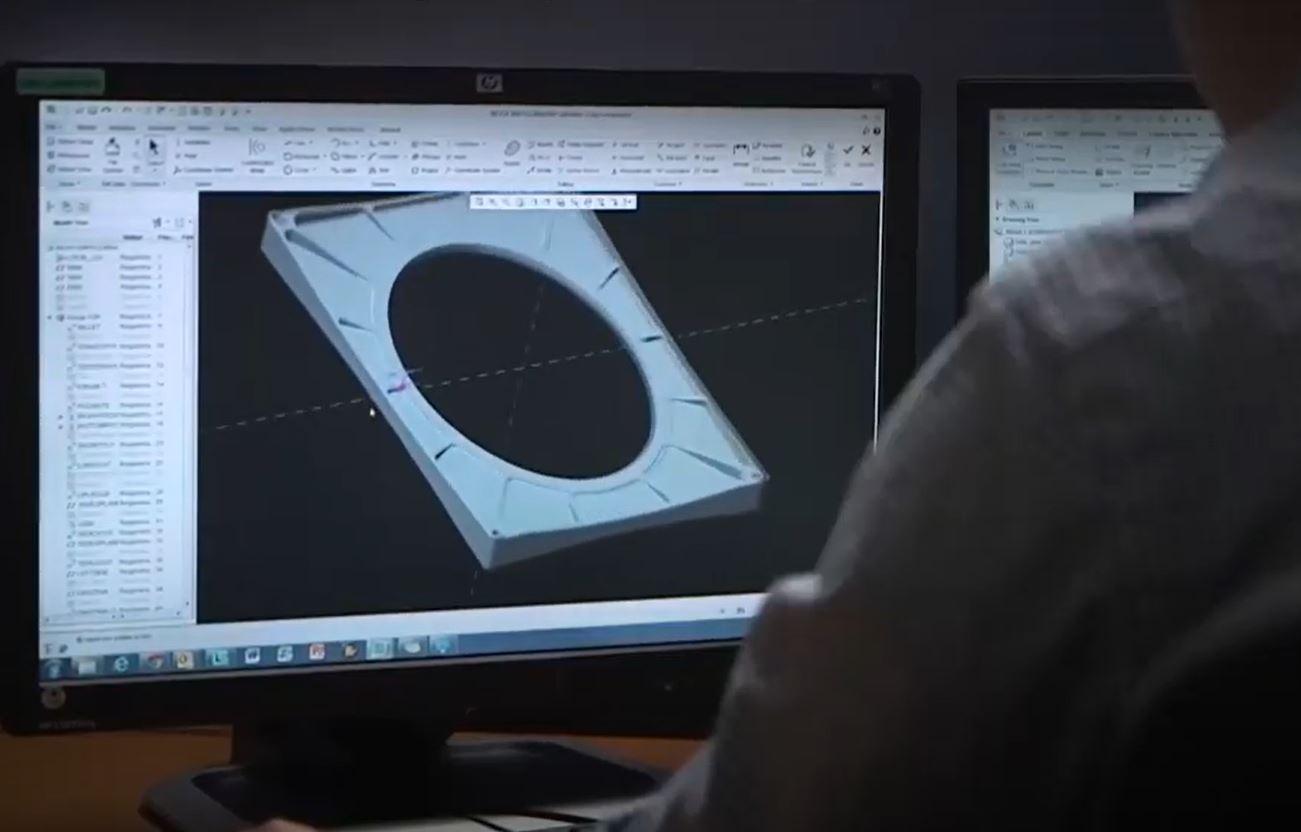

Credit: Lockheed Martin

The aerospace and defense (A&D) industry saw billions of dollars being invested across the industry in 2022. This growth was driven by several factors, including the need for new commercial aircraft, an increase in new defense programs, the growth of urban air mobility (UAM), a rise of commercial...

Subscription Required

This content requires a subscription to one of the Aviation Week Intelligence Network (AWIN) bundles.

Schedule a demo today to find out how you can access this content and similar content related to your area of the global aviation industry.

Already an AWIN subscriber? Login

Did you know? Aviation Week has won top honors multiple times in the Jesse H. Neal National Business Journalism Awards, the business-to-business media equivalent of the Pulitzer Prizes.