Multiple AI use cases are being tested for MRO, but experts caution that transparency and realistic expectations will be key.

Since ChatGPT went viral in late 2022, the artificial intelligence craze has permeated discussions in nearly every industry worldwide. Businesses have started to seriously consider how the technology could be used to boost efficiency and profits, while the world’s workforce either eagerly embraces its ability to aid in job tasks or watches its progress warily, concerned about which jobs might someday be eliminated by AI.

Within the aftermarket, AI has been gaining traction in the last few years. Startups, MRO providers, airlines and industry research centers have been developing AI-based tools to aid maintenance in a variety of ways, including inspecting aircraft and engines, creating smart hangars, building digital twins of assets and automating technicians’ ability to log records and troubleshoot tasks.

Aerospace Xelerated, a Boeing-backed technology accelerator program, has been working with many of these AI-focused startups to evaluate industry use cases and foster connections with companies that are looking to innovate. One such startup is Amygda, a UK-based company founded by former Rolls-Royce engineers that has developed a generative AI (Gen-AI) application it describes as similar to ChatGPT for MRO.

Faizan Patankar, co-founder and CEO of Amygda, says the technology “is sort of a co-pilot for engineering and maintenance teams,” accepting input queries in plain text and generating insights in an easily explained and interpreted way. Patankar says technicians can use the application to find answers to “what if” scenarios based on data—such as maintenance logs, flight hours, pilot reports and sensor data—instead of just historical information.

“For example, a technician can decide to open a chat or review an alert generated on the system by talking to the co-pilot application [and] asking questions such as: What are the potential causes for the issue?” Patankar says.

Amygda’s technology can also perform logic calculations, such as determining the remaining useful life of an asset, which Patankar says is a unique feature built into the system. “Currently, ChatGPT or other language learning models cannot do such analysis, but we are developing this layer for MRO specifically,” he adds.

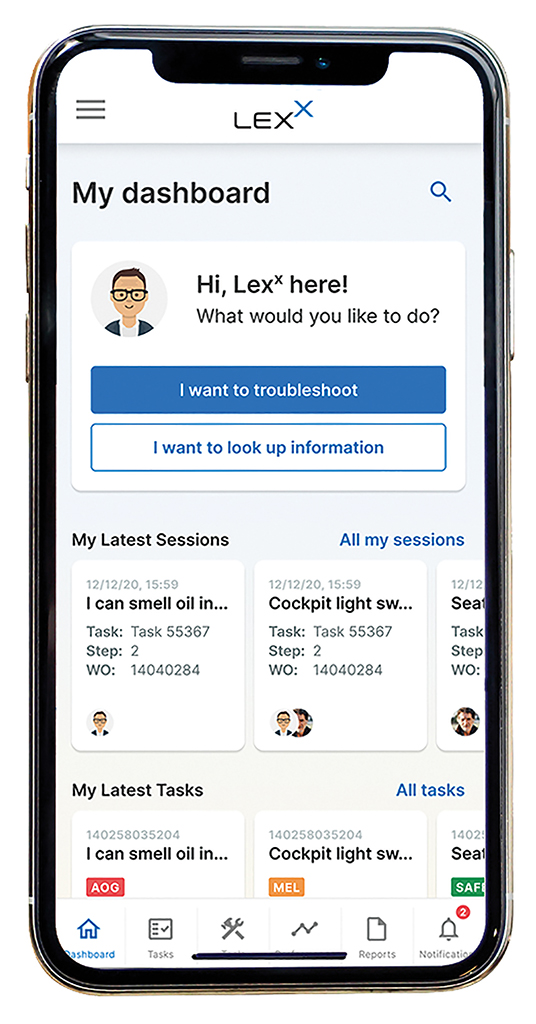

The hype around ChatGPT has also boosted customer interest for LexX Technologies, another startup that completed the Aerospace Xelerated program. Mike Harris, head of general operations, says the Australian company’s AI platform operates like a cross between Apple’s Siri virtual assistant and Star Wars’ C-3PO droid, automatically digesting data and providing answers to technicians. “So long as it’s been recorded somewhere and that can be fed to LexX to read, interpret and understand, then we can answer almost any question,” Harris says.

For an industry such as aviation, which operates on a mountain of data and specialized expertise, Harris says the LexX platform could alleviate the limitations of an average worker. “We’re now in a world where [we] only retain that which is relevant right now. We are drowning in data,” he says. “Wisdom has built up over the years, but what’s happening today is transient. But what if what’s happening is an urgent safety bulletin?”

While a worker may read safety bulletins with good intentions, Harris argues that their retention of this information may not last long. However, the LexX platform could remind technicians about the information when it is relevant and provide warnings, such as for tasks in which technicians previously experienced injuries.

Harris stresses that the company’s AI technology “learns lessons right along with you,” so technicians can benefit from institutional knowledge quickly and easily. For example, he references an industry joke in which a pilot describes an aircraft fault to a maintenance provider, which then sends two technicians to troubleshoot based on the description—one with six months of experience and another with 30 years of experience. “They’ll go to different ends of the aircraft because one will go strictly by their checklist of fault-finding and the other one will say, ‘I’ve seen this before,’ and will go off and fix it,” he says. In a scenario such as this, Harris says LexX could pass down lessons learned by the experienced technician to a company’s entire maintenance workforce.

American Airlines is exploring the use of natural language processing (NLP)—a branch of AI focused on enabling computers to understand text and spoken words—in its maintenance operations. The airline is looking at how NLP could be used to instantly log and transcribe maintenance information via speech, to identify which ATA codes should be used to classify faults and simplify the process of searching for corrective actions.

The MRO Lab at AFI KLM E&M is also exploring the use of AI for a variety of tasks. Paul Chun, vice president for technology at KLM Engineering & Maintenance, says the MRO provider is using NLP and computer vision to simplify documentation, to give technicians quicker access to documents and safety processes, and to find part numbers more quickly. It is also incorporating AI into its Prognos predictive maintenance platform.

Within Singapore’s Agency for Science, Technology and Research (A*STAR), the Singapore Aerospace Programme has developed machine learning algorithms for both text recognition and defect detection applications. Using a dataset comprised of more than 1,600 data points, it tested the algorithms using both machine-generated and handwritten text under a variety of lighting conditions. Ric Parker, chairman of the program at A*STAR, says it is working to further explore how Gen-AI tools, which learn based on input data and generate new content, could be used in the MRO industry. He adds that the program is also working with industry partners such as Singapore Airlines and SIA Engineering Co. on “several initiatives involving AI solutions and improving manufacturing capabilities,” and on AI-based shop floor intelligence projects.

An AI platform targeting improvements in both aerospace manufacturing and maintenance is Basetwo AI, which recently completed the Aerospace Xelerated program. The platform connects data sources, such as aircraft component sensors and maintenance logs, and uses this data to build simulation models of key components in an aircraft. The simulation models can be used to help companies determine when assets and equipment are deviating from expected or normal behavior.

Thouheed Abdul Gaffoor, CEO of Basetwo AI, says this functionality can be used to optimize how companies schedule maintenance activity, as well as expand the life cycle of an asset or increase its utilization rate. He notes that two promising application areas involve maintenance of aircraft engines and environmental control systems.

Some startups are leveraging AI paired with Internet of Things (IoT) technology to create smarter hangars. Fyve By has developed a system that pairs cameras, sensors and software to create a 3D replica of a hangar, providing real-time visual tracking of aircraft, cargo, tools and staff. The aim is to monitor equipment and personnel to reduce potential hazards, such as items that could interfere with the path of an aircraft. Co-founder Preston LaVangie describes the technology as similar to the 360-deg. backup cameras found in cars. The system is also capable of helping maintenance providers to position aircraft more strategically within the hangar to maximize space.

In the UK, Cranfield University’s Digital Aviation Research and Technology Centre is examining how technologies such as AI can realistically be incorporated into maintenance operations in a way that provides business benefits. Ip-Shing Fan, MRO lead for Cranfield’s digital aviation research activity, says many different technologies being tested and deployed for MRO fall under the AI label. For instance, text-based machine learning powers paperless digitalization, IoT powers some robotics and sensor technology, and automated image processing and assessment powers image-based inspections.

Cranfield’s Intelligent Hangar is putting image-based inspections to the test, combining visual cameras and thermal sensors mounted to hangar infrastructure, drones for above-wing inspections and cameras mounted to robots for ground-level inspections. “If we manage it right, we can actually see down to a rivet or even smaller than a rivet level,” Ip-Shing notes. “If we have the right workflow automation, we can have the coordination of robots and people together and change the way that we are doing things without changing the regulation or the aircraft maintenance manual that operators need to conform to.”

On a more micro level, AI is supercharging inspection tasks for aircraft engines. GE Aerospace subsidiary OC Robotics launched an AI-powered Advanced Blade Inspection Tool earlier this year to speed up on-wing inspections of GEnx engines, and it is also using AI to improve fluorescent penetrant inspections and robotics-powered CFM56 airfoil inspections.

AI has also made headway in boosting efficiency and accuracy for engine borescope inspections. GE Aerospace recently partnered with nondestructive testing specialist Waygate Technologies to explore the use of machine learning and AI to improve reliability, cycle time and consistency of these inspections. Waygate is partnered with Dutch startup Aiir Innovations, which uses AI to detect engine defects and automate inspection analysis.

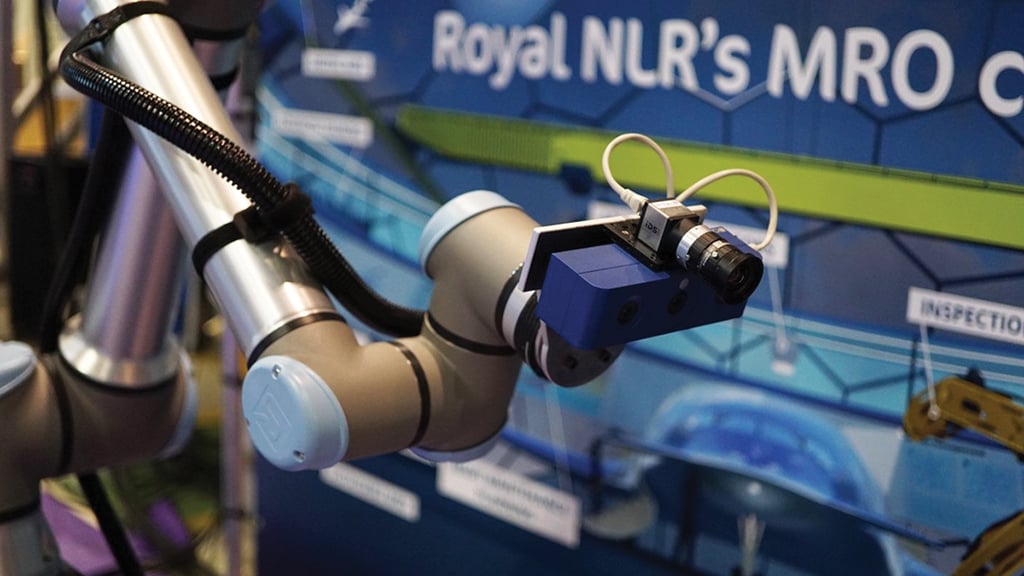

Netherlands Aerospace Center (NLR) is working on several projects to automatically or even autonomously detect damage to components such as helicopter rotor blades using cameras, robotics and software. Arjan de Jong, principal for maintenance and engineering at NLR, says these types of technologies can leverage rule-based algorithms that measure and compare data inputs such as distances and thresholds—which are much easier to quantify—but the research center is also looking into the qualification of AI to perform defect detection.

NLR is also researching the use of AI to improve maintenance planning to increase aircraft availability. “We could also use Gen-AI to fill in paperwork or make decisions,” de Jong says. “At continuing airworthiness management organizations, most of their work is done manually and they make decisions about which airworthiness directives or service bulletins to incorporate or when to perform the next maintenance. AI could take over a lot of that thinking and make decisions about whether to incorporate modifications.”

Potential Setbacks

Despite the plethora of AI-based tools and projects being explored within MRO, the technology will require thoughtful implementation to achieve industry buy-in and deliver tangible improvements.

“The true value really comes out when you embed [AI] in the right software, which needs to be inside the big ecosystem that’s already out there,” stresses Bart Vredebregt, CEO and co-founder of Aiir Innovations. “Creating a sideshow with new AI technology doesn’t help anybody. You need to be able to connect with the existing tooling in a sensible way.” The startup is currently working with engineers at Boeing to explore the right strategies for incorporating its AI technology into several of the OEM’s business segments.

Cranfield’s Ip-Shing says AI “can be an attractive label to talk to the CFO and persuade them to give me money,” but he cautions that overhyping the technology could lead to unrealistic expectations and failed investments. “There’s probably a bit of overselling by some people in the AI community,” he adds, noting that AI “needs to be coupled with the right engineering domain knowledge” to deliver actionable intelligence and results for MRO.

Vredebregt points out that the industry must be careful to avoid another “AI Winter”—or a period in which the technology loses interest and funding due to developers overpromising results and users having unrealistically high expectations, which has happened following previous periods of interest in AI.

“I think there will be moments where the technology doesn’t deliver, and the key will be handling that in a sensible way,” Vredebregt says. “Our biggest responsibility as AI companies is to make sure that we manage expectations from Day One, don’t overpromise too much and focus on delivering.”

Amygda’s Patankar notes that the startup has encountered people who expect AI to have perfect accuracy and detection rates, which he argues is a misguided perception. “For example, in medicine, AI that detects cancer has neither a 100% accuracy nor detection rate,” he says. “However, even detecting one extra case is potentially one extra life saved. It should be the same with AI in aerospace. One less engine damaged, one less aborted flight, one less flight cancellation, one less unscheduled maintenance . . . are all worth implementing an AI system that doesn’t have a 100% detection rate.”

In this vein, Vredebregt points out that humans themselves certainly do not have perfect accuracy. “Research shows humans are about 70% accurate,” he says, citing a 2022 study from the University of Canterbury in New Zealand that compared the performance of human operators with image processing, AI software and 3D scanning for different types of engine MRO inspections. The study found that AI-based systems excelled at inspection speed, consistency and reduction in false-positive rates compared with human operators.

Although the study’s results were promising, NLR’s de Jong says one of AI’s biggest hurdles is the difficulty in proving that AI generates correct results. “You put a lot of data in front of the algorithm and you get [results], but you can’t say what has happened in between and whether or not you get reliable data, so you need to make it visible,” he says. “You need to prove one way or the other that the results that come out have some validity and are reliable and trustworthy.”

He suggests the key to overcoming this hurdle is through explainable AI, which helps AI users understand and interpret predictions made by the technology. NLR has been exploring DARPA’s explainable AI technology and following initiatives from regulators such as the European Union Aviation Safety Agency to develop guidelines on how to certify the use of AI for aviation purposes.

Basetwo’s Gaffoor says the company is using explainable AI, particularly because highly regulated industries such as aviation require this higher level of visibility. “Our approach is to fuse domain knowledge by subject matter experts (SME) about specific equipment with the data, so an engineer can always inspect the equation behind the equipment,” he says. “If you’re simulating an engine, for example, there are well-defined thermodynamic equations and principles that govern how an engine behaves. Our AI system incorporates that knowledge so an engineer can inspect the results and trust the output because they can see how this model looks.”

But if AI can outperform humans and its results are transparent and trustworthy enough, does that mean technicians should worry about being replaced by the technology? Gaffoor argues that this fear is unfounded. “The calculator didn’t really replace anyone; it just replaced older workflows. Excel spreadsheets did the same thing. That’s really what AI is bringing to the table,” he says. “It’s an enablement tool that will accelerate SMEs and their workflows. It’s going to make their jobs easier, but we will always need human validation in the loop and we will always need that domain expertise.”

KLM’s Chun suggests that the technology could actually drive the creation of new jobs. “More skills will be needed and critical to secure a good usage of [AI],” he notes. “The MRO may need to hire or train new experts, such as prompt engineers, and educate all potential users to make sure they question Gen-AI results.”

Amygda’s Patankar concedes that AI will likely disrupt some jobs, “but we should be asking ourselves if a human brain that is vastly superior to any AI we have today should be used to do jobs that not-so-smart AI can do,” he says. “I believe we will see many more jobs created of a different nature than those that would be lost.”

Whether or not technicians will eventually lose jobs to AI, the MRO industry’s workforce shortage may actually be an argument in favor of AI adoption. “I understand the sentiment and the concern; however, everyone is also very aware that we’ve got this talent shortage, and the effects of it are incredibly painful for industry right now and creating ripple effects all across the ecosystem,” says Andy Hakes, founder and CEO of AireXpert. The company’s digital platform automates the collection and coordination of MRO-related data, aiming to reduce the time, energy and resources required. “I think the combination of AI and automations are simply being used to fill the gaps and won’t result in a net loss of people,” he adds.

However, Hakes says he does not see AI as a catchall solution for every challenge in MRO. “Probably 80% of the time people think that AI is necessary to solve whatever challenge it is they’re dealing with on a daily basis, but I think the majority of time—particularly because we’re still kind of lagging where we are with MRO technology—we can solve those problems with structured processes and algorithmic approaches versus jumping headlong into AI,” he argues.