As aftermarket providers tackle unique maintenance challenges in the pandemic environment, MRO software provider WinAir is developing new features to help users overcome difficulties in maintaining compliance.

During its Virtual WinAir User Summit in late 2020, the company’s aftermarket customers identified issues such as aircraft parking and storage, finding parts for aircraft types experiencing accelerated retirement and the transition to more remote working models as major obstacles in the pandemic environment.

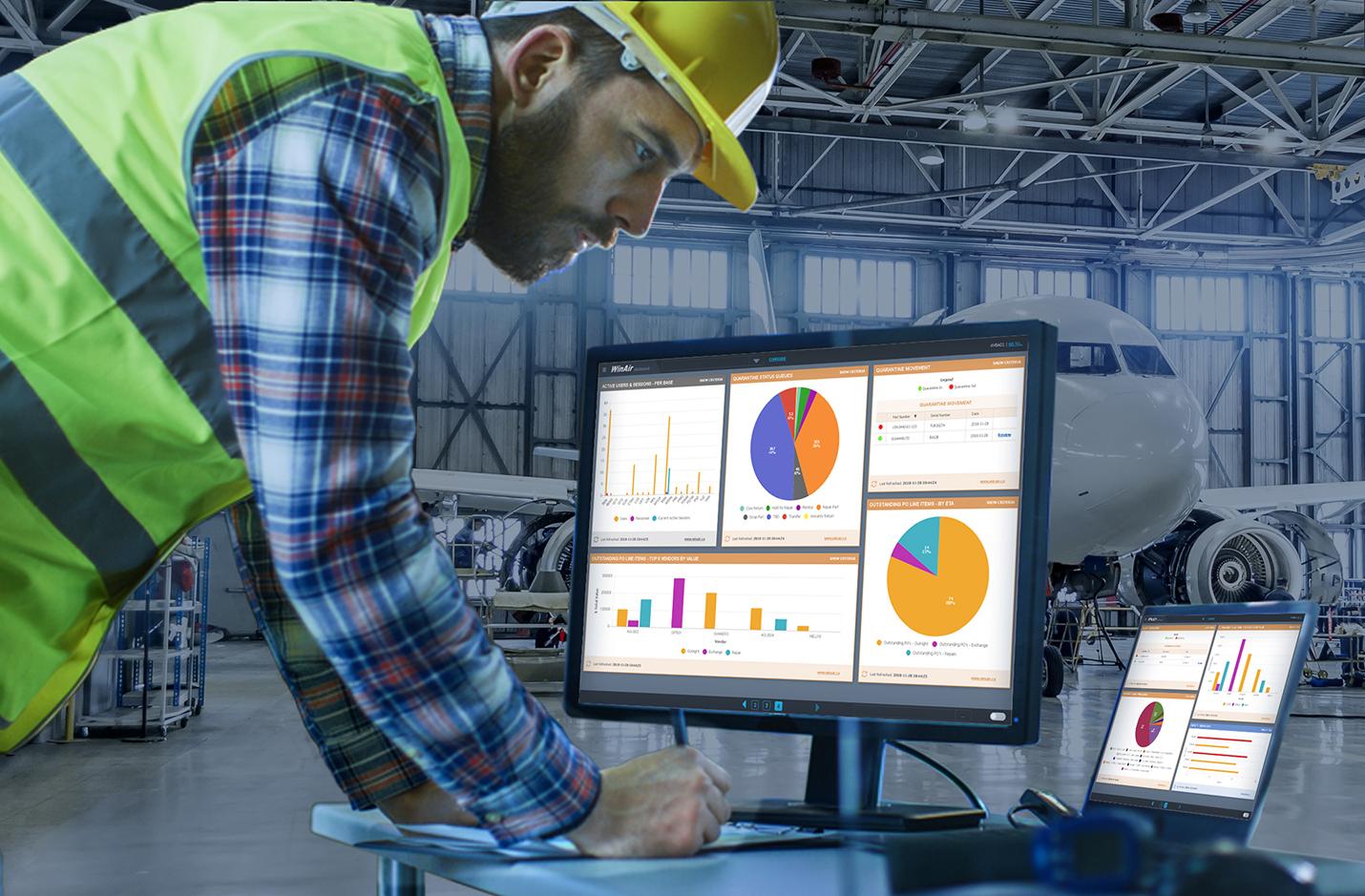

According to Kyle Vergeer, managing director, WinAir, more people holding technical roles in the aftermarket are realizing they no longer need to be at the office due to having more interactive tools online. However, he says, with physical distance comes difficulty in enforcing processes for safety management—which is where tools such as WinAir’s software come in. “We’ve got a lot of processes built directly in the application where, even though you’re not sitting side by side, you can still kind of look over each other’s shoulders and give your okay without having to sit in the boardroom together,” says Vergeer.

He notes that parked or stored aircraft and their return to service also generate a host of compliance requirements and that the pandemic has driven changes to maintenance programs, such as moving away from equalized phase checks—where operators split large maintenance checks into multiple visits to prevent an aircraft from experiencing prolonged downtime—and back toward traditional block check styles. “You might even be switching from a high utilization maintenance program to a low utilization maintenance program, which alters your intervals and things like that,” says Vergeer. “With the lower utilization they now have to be more cognizant of calendar driven requirements because they’re creeping up because they’re not flying as much.”

As a way to address these concerns, WinAir has been working on updates related to change management and the template revision process. “It’s been somewhat problematic for larger organizations to put in their own customized approach to say, ‘In order for changes to my maintenance program to take place, I want the following people to be involved on the following steps,’” notes Vergeer. “If I was planning to do my C check in London, Ontario, but a week later I realize it’s more convenient to do it in Toronto, that triggers a whole bunch of changes. I might have already put parts aside and assigned people in London. Am I going to ask them to go to Toronto or am I going to release them and assign new people?”

According to Vergeer, WinAir is working toward quickly adapting tools to help customers make decisions when changes are required, including retroactive results to help companies determine whether production floor planning is unrealistic based on historical outcomes. It is currently beta testing version 7.2 of its software, which will include new features for managing warranties on parts throughout the lifecycle, rostering and task assignment to ensure workers are not over-assigned relative to their shifts, and ways to track resource requirements and qualifications—such as whether a technician has an up-to-date passport or whether a specific location has the right personnel and parts available to perform maintenance that is coming due.

Vergeer notes that a major push will be enhancements to WinAir’s reliability offering. “This is an area that we feel that we’re going to be in a league of our own. Manufacturers are requesting, if not mandating, that operators send them the results of maintenance so that the manufacturers can compile the fleet reliability data, and it’s really helpful for those manufacturers to help minimize the maintenance requirements without compromising reliability,” he says. However, Vergeer points out that this data does not provide much value individually. “If I could take my reliability data and compare it with all the other WinAir operators of the same aircraft type where there’s a community of comparable reliability data, it’s going to be a game changer because you’ll be able to get that manufacturer level of fleet reliability data without having to go through the manufacturer.”

According to WinAir, new features will be released in phases throughout 2021. And while money is still tight for most companies in the aftermarket, Vergeer says the pandemic has provided opportunity for technology providers to prove their value proposition. “There’s been a bit of breathing room for some people to make changes in their organizations because they’re not chasing down that AOG because their aircraft are flying less,” he says. “I’ve seen that people have not stopped working, but they’ve taken the opportunity to address things that they haven’t had time for in years.”