Business aviation is a naturally conservative sector of the industry as its unwavering dedication over the past half century to tried and trusted tube-and-wing aircraft configurations clearly shows.

But times are changing, and despite impressive reductions in fuel burn and emissions over recent years, business jet makers are increasingly under scrutiny to search for more innovative solutions as the industry seeks to be net zero carbon by 2050.

However, while business aviation has often been the bellwether of new safety and cockpit systems technology in the past, it’s unique needs for range, cabin size and airfield access make it one of the hardest sectors to take advantage of potential new low-emission propulsion technology areas such as hybrid-electric or hydrogen power.

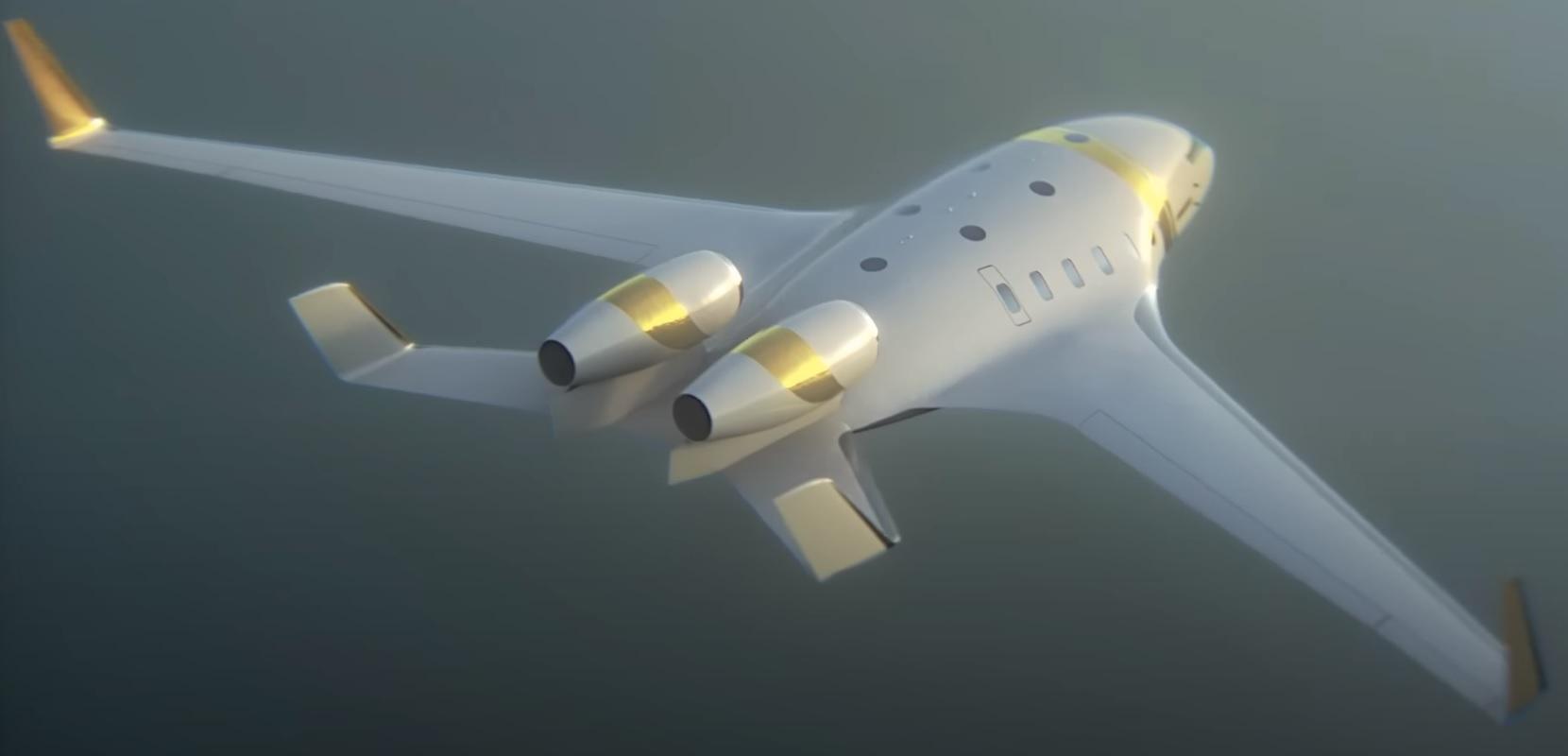

Despite these limitations, business jet maker Bombardier has been the most public in pushing the edges of the design envelope by studying a blended wing body (BWB) configuration dubbed the EcoJet which aims to halve emissions through a combination of aerodynamic and propulsion improvements. The company, which is expected to provide an EcoJet update at EBACE this week, has been flight testing sub-scale versions and simultaneously exploring associated advanced systems and structures technologies.

Speaking to Aviation Week at last year’s National Business Aviation Association (NBAA) show in October, Eric Martel, president and CEO of Bombardier, disclosed the company had recently begun flying an 18-ft.-span subscale demonstrator of its EcoJet design and was optimistic the configuration had the potential to reduce emissions by 18-20%. “When we do launch a new program we will incorporate some of these new technologies,” he said at the time.

The timing of such a bold move remains unknown and much depends on the outcome of the ongoing studies. Using data from the 2022 subscale demo flights, Bombardier planned to “characterize the plane and aerodynamics to validate the potential emissions savings. It’s going to take a while and I don’t know if this will be the shape or something similar, but we can definitely see it coming in a reasonable amount of time,” Martel said.

The BWB concept blends both the airframe structure and aerodynamics to enable the fuselage to contribute significantly to lift and has been under study for larger applications since the 1990s. Sometimes also known as a hybrid wing body, the configuration is usually more efficient than a conventional tube-and-wing design because of its reduced wetted area and lower form drag. The BWB is also inherently quieter than conventional configurations with wing or fuselage-mounted engines because the airframe shields most of the noise from the upper-surface-mounted engines.

But BWBs face several inherent design challenges, ranging from structural efficiency and passenger egress to adequate pitch authority. To overcome some of these, Bombardier’s EcoJet has been optimized through a Canadian research program, the Green Aviation Research and Development Network (GARDN), to create a design which is a hybrid BWB with a slender lifting fuselage, a U-shape tail and distinct high aspect ratio wings.

Although the original GARDN project, which ran from 2009 to 2021, was aimed at a 100-seater regional airliner, the EcoJet design has successfully scaled this down to business jet size with rear-mounted turbofans shielded by the tail. While the tail helps address pitch control concerns, the company is still researching options for the fuselage and non-circular cabin, which Bombardier has constrained to a usable volume equivalent to that of its Global 6500 large-cabin, long-range business jet.

Another concern is whether a BWB lends itself to a portfolio of aircraft. Bombardier expects that the BWB is probably best for longer range business jets given the relative benefits of the design over shorter stage lengths.

The chances of BWBs becoming a reality have meanwhile increased with the revelation in April that JetZero—a California-based startup—has outlined plans to develop a blended design for an emerging U.S. Air Force requirement for a future tanker. The program, which would involve Northrop Grumman on the military side, would also evolve into a commercial derivative aimed at the mid-market sector—for which neither Airbus or Boeing currently have an offering.

The JetZero design is itself evolved from a scalable BWB concept developed by Dzyne Technologies, which included a business-jet version similar in range and speed to the G650. However, due to design innovations, including a pivoting nose gear which increased body angle pitch angle on takeoff and landing, the designers claimed the BWB would offer several advantages. It was estimated field length required for a 7,000 nm-plus mission was reduced by almost half compared to the Gulfstream aircraft. At the same time, floor area per passenger was tripled and fuel burn per passenger mile was reduced by around 20%.

With sustainability likely to be among the key topics at EBACE, other business aircraft manufacturers are also expected to update efficiency initiatives. Among these is Embraer, which at NBAA in 2022 unveiled a vision concept intended to illustrate how technologies could shape a future design.

Configured around elements such as autonomous flight, the vision vehicle was outlined as a super-midsize aircraft with a three-zone cabin typical of a large business jet. The aircraft was also defined with a 100% sustainable propulsion system based on either sustainable aviation fuel, electrification and/or hydrogen. The aircraft’s two engines were mounted one above the other between the V-tails, staggered longitudinally to meet certification requirement for rotor burst zones.