COLORADO SPRINGS—Almost a year after its ruggedized HPE Spaceborne Computer-2 (SBC-2) was installed on the International Space Station (ISS), Hewlett Packard Enterprise says its advanced artificial intelligence (AI)-enabled processor system has completed 24 research experiments and accelerated data analysis time from months to minutes.

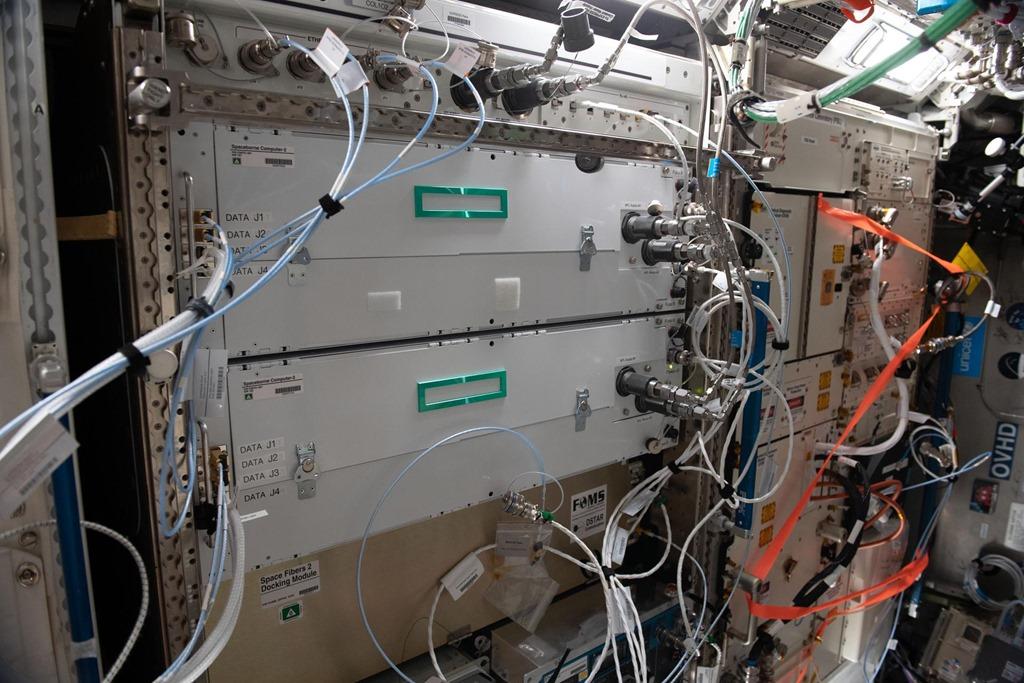

Incorporating the Texas-based company’s Edgeline Converged EL4000 Edge system and ProLiant DL360 server, the SBC-2 was launched in February 2021 and installed on the ISS in May. Enabling much faster computing and shorter download times than previous space-based systems, the SBC-2 also forms part of a larger steppingstone mission to advance computing and reduce dependence on communications with Earth as humans travel farther into space to the Moon, Mars and beyond.

Hewlett Packard made the announcement at the Space Symposium, being held here April 4-7.

The company says the SBC-2 has the capability to download data to Earth at radically compressed size and faster speed. Previously, 1.8 GB of raw DNA sequence data took an average time of 12.2 hr. to download for initial processing. With SBC-2, researchers on the ISS have been able to process the same data in 6 min., compress it to 92 KB and send it to Earth in just 2 sec., representing a 20,000-times increase in speed.

Experiments highlighted by Hewlett Packard during the first year include work with NASA and Microsoft on an AI-enabled damage detection process for astronaut gloves, as well as a project with NASA Jet Propulsion Laboratory to test deep learning inference networks to automatically interpret remotely sensed images of land and structures after a disaster.

Others included experiments with Cornell Fracture Group, part of Cornell University, to test modeling software that simulated 3D printing of metal parts and predicted any failure and deformation that could result from printing in the harsh conditions of space. “The software was successfully tested on Spaceborne Computer-2, validating that it can be used in space to digitally simulate a part and understand how it will perform in reality,” the computer maker says.

The system was also used to help demonstrate the potential to install state-of-the-art 5G capabilities on selected satellites and spacecraft to develop an improved level of communications in space, as well as to develop code to calculate fuel requirements based on space travel distance.