LAS VEGAS—As the business aviation sector looks increasingly to propulsion technology for improved sustainability, Honeywell Aerospace is paving the way for a more efficient next-generation turbofan through an ongoing series of advanced test and development programs.

Working since 2010 under the first two phases of the FAA’s long-running Continuous Lower Energy, Emissions and Noise (Cleen) program, augmented by internal research and development, Honeywell has focused initially on engine core efficiency improvements and testing with sustainable aviation fuels (SAF).

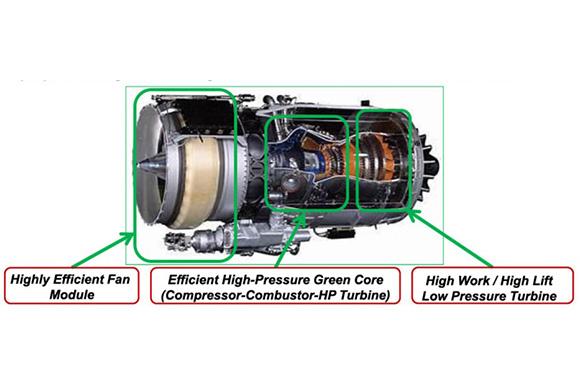

For Cleen Phase II, the engine-maker continued its high-pressure core work with evaluations of a compact combustor, an advanced turbine blade outer air seal and high-pressure (HP) compressor. Related tests of a compact combustor were completed in 2022 on NASA Glenn Research Center’s advanced subsonic combustion rig. Now working under Cleen Phase III, Honeywell is continuing its high-pressure core work, but is adding new project areas covering studies of a compact high work, high-lift, low-pressure (LP) turbine and a highly efficient fan module.

“The FAA is providing us with funding to mature this but at the same time our business has also been quite supportive, and they are augmenting some of the investments from the FAA to do that,” says Sunil James, director of Advanced Propulsion and Power Systems, Honeywell Aerospace. “They want my team to go fast. They want the technologies to mature next year. So, it’s a great time for us.”

Aimed at the next generation super midsize business jet sector for entry into service notionally around 2031, the advanced HP core, low-emission combustor and efficient HP turbine project is expected to reduce noise by around 3 EPNdB and fuel burn by up to 8.3% relative to current engines in the HTF7000 class. Emissions are similarly targeted to be cut dramatically—in this case to levels with around a 70% margin to CAEP/8 standards for NOx, as well as a 70% reduction in nonvolatile particulate matter (nvPM).

“We are focusing front to back on how we improve aerodynamic efficiency,” says James. “How do we improve durability? There's a lot of focus on reducing fuel burn, emissions and noise. How do we increase overall pressure ratio; how do we increase T4 turbine entry temperature? Those are classic strategies to drive down fuel burn and that strategy is never going to go away.”

For reducing emissions, the company is focused on combustor improvements and “from an acoustic perspective, we are trying to attack the source of noise generation within the turbo machinery in addition to noise treatment,” says James. “At the same time, we're keenly looking at how to avoid dramatically increasing the weight of the engine.”

The high-pressure core project is expected to reach a technology readiness level (TRL) of 5 by early 2024 and reach the pre-full-scale development TRL 6 level by the end of 2025. The fan module and LP turbine projects are likewise targeted at TRL 6 by late 2025, having passed the TRL 5 milestone by late 2024 and early 2025, respectively.

For the high-pressure turbine, the focus is on infusing advanced high temperature materials, “as well as looking into non metallics as well to increase the core temperatures,” says James. For the combustion system studies he adds “there is a significant tradeoff between emissions and operability. We are trying to address if there is an opportunity to break that trade? Can we drive down emissions without impacting operability?”

“We completed all our design work early this year on the fan, the compressor the turbine, and we are right now in the hardware procurement phase,” says James. “We also have a few tests coming up, some of which are ongoing right now in the fourth quarter. But there is a lot of testing happening next year to validate our designs and see where we fall on all the three metrics for fuel burn, emissions and noise,” he adds.

Core tests are targeted for 2024. Combustor rig and tests in a complete engine to TRL 5 levels have meanwhile continued since 2021 with final tests expected in late 2024. Honeywell says initial combustor design rig tests have showed “good progress” toward lower NOx and nvPM, while HP turbine material and coating tests continue to show “promising results” for thermal capability and protection.

The advanced fan module will incorporate new acoustic treatments and optimized fan exit guide vanes and booster stators to reduce noise by around 1.5 and fuel burn by 1.5%. The improved LP turbine, which will be lighter and more efficient, is meanwhile expected to cut noise by 0.5 EPNdB and fuel burn by as much as 2.5%. Both the fan and LP turbine modules are scheduled for fabrication and assembly in 2024 and will be tested at the end of next year.

“There is a lot of focus on the LP turbine because there is an opportunity to drive down weight with very advanced aerodynamics of the turbine blades and the whole low pressure turbine system. We feel it would be quite impactful for overall fuel burn of the engine,” says James.